Source factory & No middleman !

Carbon Vane manufacturers In China

- Best Price & Large Quantity Discount

- Offers over 100 standard products and supports customization

- Personal engineer for full one-on-one support

With more than 30 years of experience in the carbon vane industry, JCL Carbon has advanced precision CNC machining and milling equipment.

JCL Carbon has several production lines, CNC milling machines, Sawing machines, vacuum package and other machines

From communication to order confirmation, product production and processing and after-sales have exclusive engineers and you docking!

Focus on Carbon Vane Manufacturing

JCL Carbon is the leading Carbon Vane manufacturer based in Nantong, China since 2006. We offers different size carbon vanes for vacuum pump. Such as for Becker pump. We can produced over 100+ standard carbon vanes. Plus, we can offer custom options too.

Exterior wall insulation board new energy-saving

- Thermal conductivity: 0.01234W/(m·K)

- Low Temperature Bending: 0.4564

- Elongation at Break: 0.2645%

- Firmness: 0.454

- Operating Temperature: 1000°C

There are various standard colors, and special colors can be customized.

- Thermal conductivity: 0.01234W/(m·K)

- Low Temperature Bending: 0.4564

- Elongation at Break: 0.2645%

- Firmness: 0.454

- Operating Temperature: 1000°C

Fermentum ornare vel vestibulum suscipit sed magna efficitur.

- Thermal conductivity: 0.035W/(m·K)

- Bending strength: 350MPa

- Elongation at Break: 0.024%

- Firmness: Moderate

- Operating Temperature: 350℃

Low thermal conductivity, good sealing and insulation effects.

- Insulation system: 0.1023

- Thermal conductivity: 0.0125

- Elongation at Break: 0.1023

- Low temperature bending: 0.102

- Color: Customizable

Sound-absorbing and noise-reducing, fire-retardant and flame-retardant.

- Insulation system: 0.1023

- Thermal conductivity: 0.0125

- Elongation at Break: 0.1023

- Low temperature bending: 0.102

- Color: Customizable

Thermal insulation, reducing energy consumption by 70%.

- Thermal conductivity: 0.035W/(m·K)

- Bending strength: 350MPa

- Elongation at Break: 0.024%

- Core material: Rock wool

- Operating Temperature: 350℃

Low thermal conductivity, good sealing and insulation effects.

- Insulation system: 0.1023

- Thermal conductivity: 0.0125

- Elongation at Break: 0.1023

- Low temperature bending: 0.102

- Color: Customizable

Sound-absorbing and noise-reducing, fire-retardant and flame-retardant.

- Insulation system: 0.1023

- Thermal conductivity: 0.0125

- Elongation at Break: 0.1023

- Low temperature bending: 0.102

- Color: Customizable

Thermal insulation, reducing energy consumption by 70%.

- Thermal conductivity: 0.035W/(m·K)

- Bending strength: 350MPa

- Elongation at Break: 0.024%

- Core material: Rock wool

- Operating Temperature: 350℃

About JCL Carbon

JCL CARBON was established in June 2004, covering an area of 40,00 square meters, including 20,00 square meters of plant area.

The company is located in the beautiful scenery of Nantong Haimen County, is the earlier domestic use of advanced technology to produce Carbon Vane products.

We can produce many size carbon vanes for different brand vacuum pump. such as: BECKER,BUSCH,DVP,ELMO RIETSCHLE,HEIDELBERG,ORION,REPUBLIC,SCHMALZ,DURAVANE,GAST And other pumps!

Production Process

Raw Material

Carbon Vanes, used in the Vacuum Pump, are primarily made from graphite, with the addition of metal powders and binders. These materials are carefully chosen to balance electrical conductivity, wear resistance, and self-lubricating properties.

- Carbon graphite

- Electrographite

- Resin-bonded graphite

Fabrication

Carbon vanes are produced by mixing fine carbon powder and resin, pressing it into a die, and then baking it at high temperatures to form the final vane. The process involves several steps, including shaping the composite mixture, achieving the correct density, and hardening it through heat treatment.

- Raw Material Preparation

- Mixing and Molding

- Heat Treatment

- Machining and Finishing

- Impregnation

- Surface Treatment

Quality Inspection

Quality inspection of Carbon Vanes is crucial for maintaining the performance and extending the lifespan of electric motors and generators. Regular checks and replacement as needed can prevent costly repairs and downtime.

Visual Inspection

Dimensional checks

Performance & Electrical checks

Brush holder and commutator inspection

Other important considerations

Packing

When packing carbon brushes for shipping or storage, focus on protecting them from damage and moisture. Use padded envelopes or blister packs for lighter shipments, and consider individual packaging with anti-static bags for sensitive brushes. Ensure brushes are clean and dry before packing, and avoid over-tightening any packaging materials that could damage them.

Clean and Dry

Individual Packaging

Secure Placement

Appropriate Packaging

Avoid Over-Tightening

Label Clearly

Moisture Protection

Shipping

First, we work with top logistic, courier and Freight agent allowing us the most competitive transit time and pricing.

Second, we supply packing material like carboard boxes, or on pallets depending on the material size of your order. We can do that !

More than 300 SKU Stock

Strong Packing

Fast delivery

Truthful Supplier

Application

Carbon Vanes are widely used across numerous industries due to their essential role in facilitating electrical current transfer in rotating machinery like motors and generators.

Packaging And Printing

Carbon vanes are used in dry-running conditions. such as packaging and printing, that are essential for vacuum pumps used in packaging machines.

This is the heading

Carbon Vanes are integral to large industrial motors and generators used in manufacturing facilities, steelworks, and power plants.

Automotive Industry

Carbon Vanes are used in various automotive applications, including starter motors, windshield wipers, and power windows.

Renewable Energy

Carbon Vanes play a critical role in wind turbines, ensuring reliable power generation.

Medical Technology

Carbon Vanes are essential for CT scanners and other medical equipment requiring low-noise and precise power transmission.

Crane Industry Systems

Carbon Vanes are used in overhead cranes and other material handling systems.

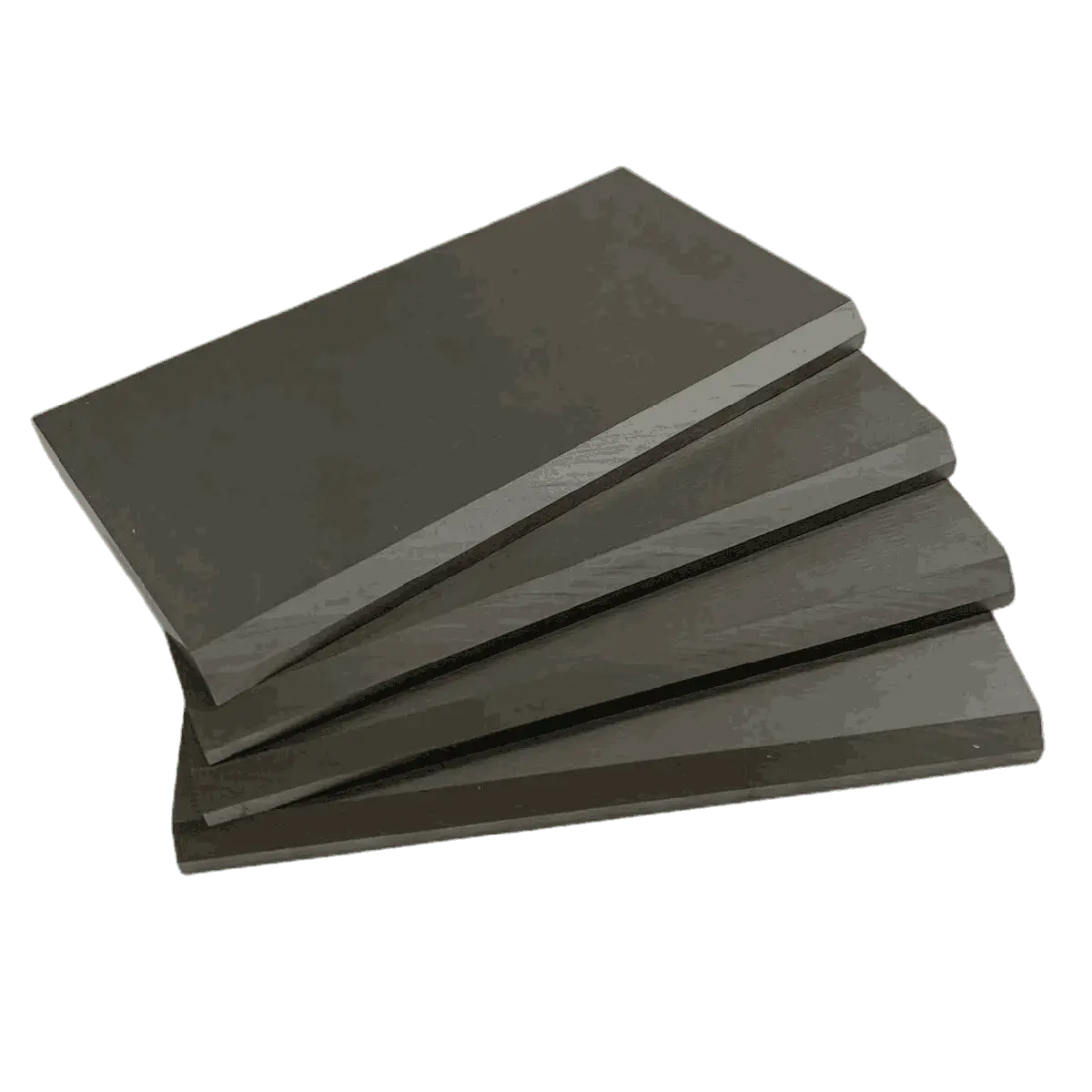

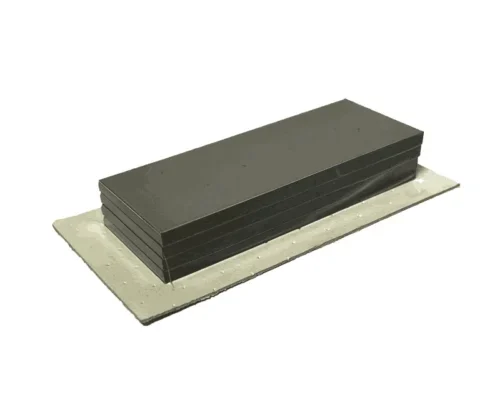

customized service

- Carbon Graphite Plate: Carbon plate/Kevlar plate

- Core Material: EK60/KEVLAR

- Lengths: 170/250/355mm(According to customer needs)

- Surface: Plain/Bright/Smooth/flat

- Thickness: 1/3/4/5/10/20mm(According to customer needs)

- Color: Black/Green/Yellow/Special colors can be customized

Professional, enthusiastic and reliable Carbon Vanes specialists

I am Toby. I have 8 years of experience in the Carbon industry, which allows me to quickly understand your needs and develop the most suitable procurement plan for you.

Common Questions

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

We offer a range of core materials for our PU Sandwich Panels, including polyurethane, rock wool, and glass wool. Each material is selected for its specific properties, such as insulation performance and fire resistance, to best suit the requirements of different construction projects.

Absolutely! You can choose the size, type of metal for the outer plates, and even the color and texture. We make sure everything fits just right for your project.

Our panels are really tough against fire and great at keeping the heat where you want it. They help make your space safer and more comfortable while saving on heating costs too.

We offer a range of core materials for our PU Sandwich Panels, including polyurethane, rock wool, and glass wool. Each material is selected for its specific properties, such as insulation performance and fire resistance, to best suit the requirements of different construction projects.

Our panels are really tough against fire and great at keeping the heat where you want it. They help make your space safer and more comfortable while saving on heating costs too.

Reviews From Customers

Want to find the source factory to save money in the middle?

With a source factory where Carbon Vanes can be customized in terms of size, carbon type, and even color and texture, and with years of experience in production, choose us to maximize our benefits.

We'd like to work with you!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.